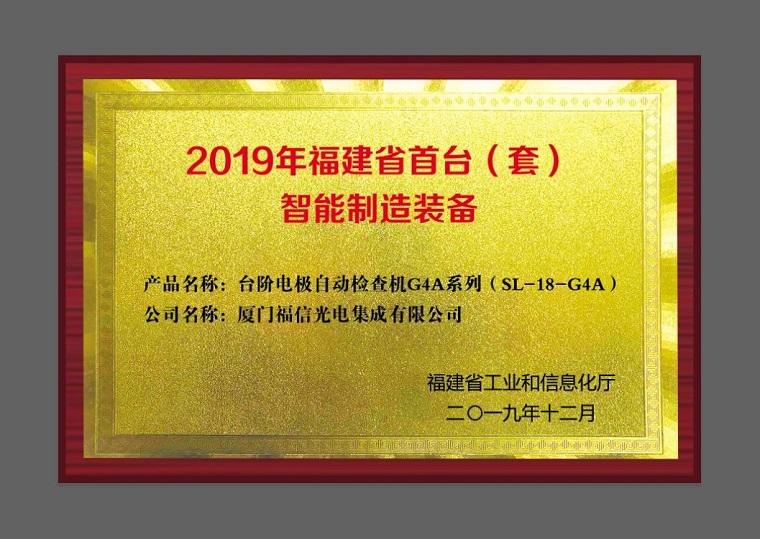

Recently, the Department of Industry and Information Technology of Fujian Province announced the list of the first intelligent manufacturing equipment in Fujian Province in 2019. Xiamen Fuxin Optoelectronics Integration Co., Ltd. (hereinafter referred to as "Fuxin Optoelectronics") and other seven units stood out among many projects and were recognized as the first intelligent manufacturing equipment project in Fujian Province in 2019. This product has 2 patents for invention and 8 patents for utility model, integrating optical, mechanical, electrical, software, artificial intelligence and other technologies. It has made innovative breakthroughs in principle, structure, performance and other aspects, filling the gap of automatic defect detection for step motor of display panel in China, and its main technical indicators have reached the domestic leading level.

Step electrode automatic inspection machine is a key equipment for intelligent detection of complex circuit defects behind display panels (including TFT-LCD, OLED, MicroLED and other displays). The defect characteristics of the circuit components of the display panel have very low contrast, fuzzy edges, defect size may be less than 0.01mm2 and easily covered by the surrounding lines. Due to the interference of fatigue, subjective influence and other factors, it is difficult to meet the requirements of high efficiency and high accuracy in human eye detection. Therefore, it is particularly important to automatically and intelligently detect the defects of the display panel step circuit components. The equipment consists of four system modules: material loading system, electromechanical control system, image acquisition system, image recognition system, etc; In the electromechanical control module, we use PLC neural network self-learning control pulse laser ranging technology to achieve automatic focusing; At the same time, in the image acquisition module, we innovatively adopted the optical auto focusing system and DIC optical differential interference technology to achieve high-speed acquisition of high-resolution images. In the image recognition module, we use the traditional image recognition algorithm and the AI artificial intelligence depth learning compound technology of depth learning to detect defects, greatly improving the detection accuracy and speed; Finally, the detection resolution can reach up to 1 μ m/pixel, reducing the miss detection rate to 0, and the single chip detection time within 12.3 inches is ≤ 10 seconds.