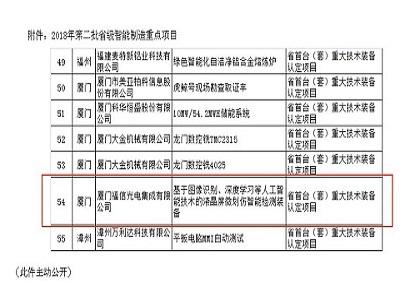

The company's project won the 2018 Fujian Intelligent Manufacturing Key Project

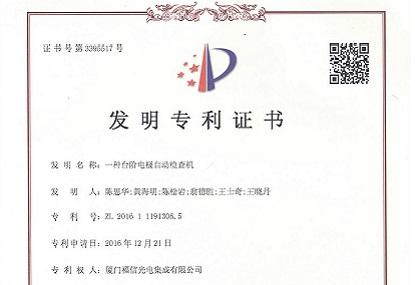

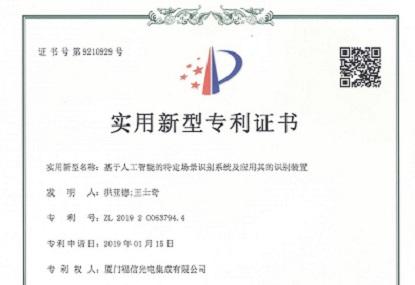

In recent years, Fujian Province has vigorously promoted the development of intelligent manufacturing, promoted industrial transformation and upgrading, and promoted the application of the new model of intelligent manufacturing. A batch of enterprises with outstanding intelligence level in products, production processes, management, services and other fields have emerged all over the country. Among the projects recommended by various places, Fujian Provincial Department of Industry and Information Technology organized, prepared and issued the Notice on the Second Batch of Key Projects of Provincial Intelligent Manufacturing in 2018. Fuxin Optoelectronics "LCD micro scratch intelligent detection equipment based on artificial intelligence technologies such as image recognition and deep learning", as the first major technical equipment certification project of provincial intelligent manufacturing province, was successfully selected into the "Second Batch of Key Projects of Provincial Intelligent Manufacturing in 2018", which is the affirmation of relevant government departments for Fuxin Optoelectronics' achievements in innovation and upgrading over the years, and also provides strong support for the company's future comprehensive development. It is reported that in 2018, the second batch of key provincial intelligent manufacturing projects totaled 68, including 38 technical innovation projects and 30 first (set) projects. The projects listed in the provincial smart manufacturing key project library this time are in principle the key support objects of the provincial smart manufacturing special funds, and also the priority recommendation objects for applying for national smart manufacturing related projects. Local supporting policies also give priority support to provincial smart manufacturing key projects. Over the years, Fuxin Optoelectronics has always been driven by independent innovation. The LCD micro scratch intelligent detection equipment developed based on artificial intelligence technologies such as image recognition and deep learning has achieved good results in the use of large flat panel display manufacturers such as Youda Optoelectronics, Tianma Microelectronics, and Zhonghua Picture Tube, which can significantly improve the detection efficiency of intelligent detection equipment and reduce the work intensity of detection personnel. With the application of our AI technology in this product, the detection accuracy can be improved by more than ten times, which will make the performance of existing image detection products leap qualitatively. We will base ourselves on manufacturing industry and replace manual inspection. In visual inspection, AI artificial intelligence is integrated to enable it to surpass traditional solutions and be competent for more challenging applications. On this basis, we will expand the application of industrial robots and realize smart factories.

Consultation Hotline:86-0592-3799658、86-137 9991 1773(Switchboard)

Consultation Hotline:86-0592-3799658、86-137 9991 1773(Switchboard)