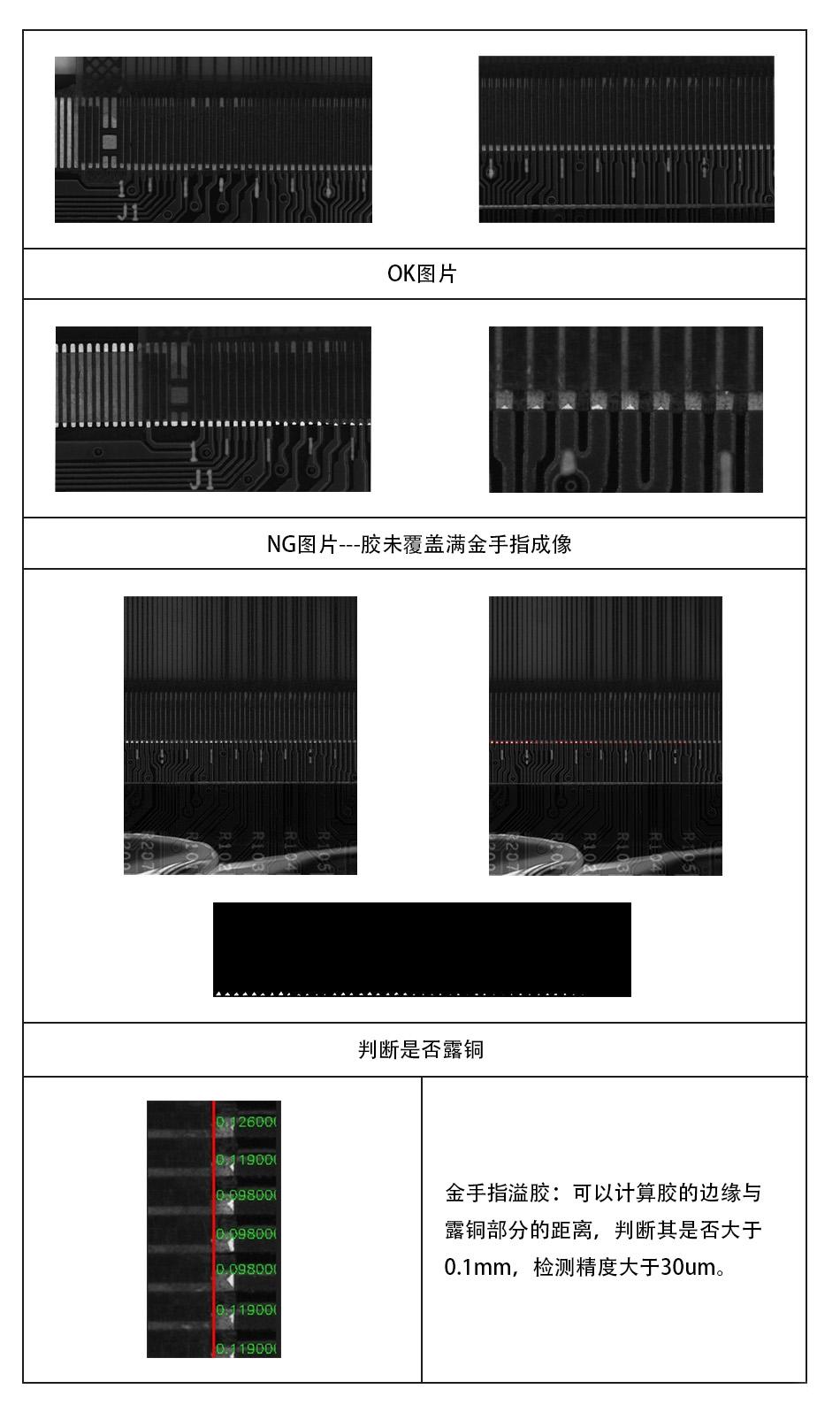

FPC bonding can achieve efficient and stable circuit connections. ACF adhesive is used for bonding TAB or COG of LCD panels, which requires high technical content and accuracy. After PCB bonding, ACF gold finger overflow defects often occur. This machine mainly detects ACF gold finger overflow defects to improve the production line yield.

|

Project |

Performance index |

|

Machine functions |

After PCB bonding, ACF gold finger overflow defect was detected |

|

Detection area |

FPC area |

|

Detected Defect |

If the overflow range is less than 0.1mm, it is judged as NG positioning |

|

Maximum detectable product size |

C145 single P board size 266 × 42 mm, finished product size (cell+FPC+P board) 361 × 173 mm |

|

C131 single P board size 275 × 40 mm, finished product size (cell+FPC+P board) 307 × 215 mm |

|

|

Detection accuracy |

Can detect defects above 30um |

|

Detection speed |

Can adapt to conveyor belt speeds of 2000-2500 mm/minute |

|

Detection Process |

Automatically identify whether there are LCD modules passing through the conveyor belt and automatically take photos of the LCD modules passing through the conveyor belt; A LCD module will capture several images; |

|

Automatically recognize the barcode of the LCD module, and store multiple images of each module in the industrial computer according to the directory name (barcode number) of each module based on different barcodes. If NG products (insufficient glue overflow) are found, an alarm will be triggered and a signal will be sent to the PLC to stop CV operation; |

|

|

Manually adjust the position of the image acquisition camera and barcode recognition camera to adapt to different specifications of LCD modules; |

|

|

Optical system |

Configure two 5-million-color array cameras, one for image acquisition and one for barcode recognition; |

|

Configure 2 sets of optical systems (including light source, lens, etc.), one for image acquisition and one for barcode recognition; |

|

|

Maximum image capture width |

16 mm |

|

Detection accuracy |

≥30 um |

|

Pixel accuracy |

7 um/pixel |

|

FOV |

16.9mm × 14.1mm (overflow detection) |

Application area

After PCB bonding, ACF gold finger overflow defect was detected

缺陷图片

缺陷图片