Automatic soldering machines are mainly used in the electronic manufacturing industry, targeting soldering processes that are difficult for production equipment to complete such as reflow soldering and wave soldering. They are particularly suitable for soldering sensitive components in mixed circuit boards, thermal sensitive components, and SMT post-processing. Automatic soldering robots replace manual soldering, improving work efficiency and welding quality.

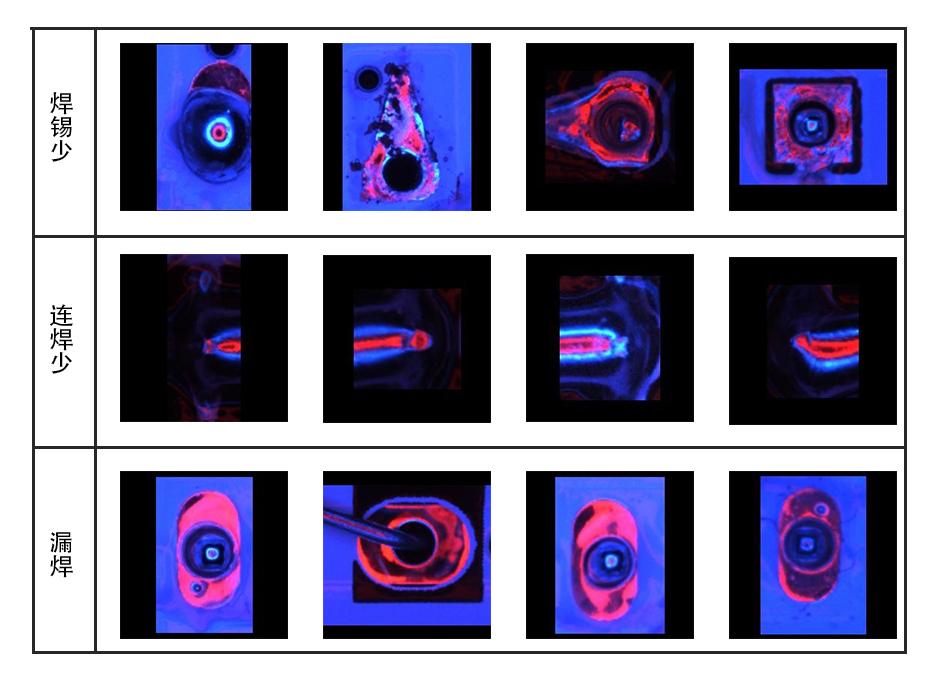

Our AOI visual automatic soldering machine has added AOI defect detection with AI deep learning function on the basis of the original automatic soldering machine. It can mainly detect defects such as solder leakage, continuous soldering, insufficient soldering, and excessive soldering, monitor the soldering quality in real time, and improve the yield rate.

The AOI visual inspection module can be integrated with friendly soldering machines to add AOI defect detection functionality. This module can also achieve CCD visual positioning, quickly and automatically finding solder joints, thereby saving programming time for single point positioning.

|

项目 |

性能指标 |

|

Equipment functions |

Widely used to replace manual soldering stations, such as PCB soldering, charger plug soldering, connector soldering, DC terminal soldering, LED light strip connection, and other fields |

|

Testing items |

Leakage soldering, continuous soldering, insufficient soldering, excessive soldering, wrong hole penetration, etc |

| Vision system |

The visual imaging system includes a 130W/500W camera, lens, and professionally customized combination ring light source, mounted on a robotic arm, to image solder joints. After welding, achieve AOI defect detection of solder joints |

|

Single detection time |

0.2s |

|

False alarm rate |

<5% |

|

Positioning accuracy |

+/-0.02mm, 0.01 ° |

|

Program storage |

2G/999 programs, 4000 points |

Extended application

The AOI visual inspection module can also be connected to automatic screw locking machines, glue dispensing machines, foot cutting machines, willow nail machines and other equipment.

Defect image