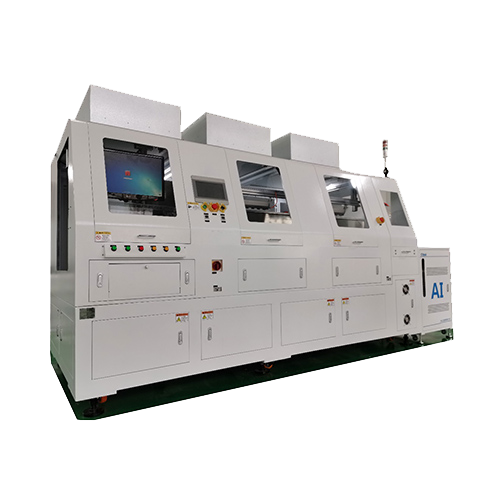

The ACF conductive particle indentation+foreign object inspection machine is used to detect the ACF conductive particle indentation and bonding foreign objects on the COG and FOG parts of the bonding section of the LCD panel, including the number, distribution, indentation strength, deviation, and various foreign objects of the conductive particles. Its core technology is the use of infrared and differential interferometry techniques, using a line scan camera to optically image the bump area on the COG and FOG of the liquid crystal panel. The image is analyzed using traditional image algorithms and AI deep learning algorithms to ultimately confirm whether the target detection object is qualified.

View More

Consultation Hotline:86-0592-3799658、86-137 9991 1773(Switchboard)

Consultation Hotline:86-0592-3799658、86-137 9991 1773(Switchboard)