The ACF conductive particle indentation+foreign object inspection machine is used to detect the ACF conductive particle indentation and bonding foreign objects on the COG and FOG parts of the bonding section of the LCD panel, including the number, distribution, indentation strength, deviation, and various foreign objects of the conductive particles. Its core technology is the use of infrared and differential interferometry techniques, using a line scan camera to optically image the bump area on the COG and FOG of the liquid crystal panel. The image is analyzed using traditional image algorithms and AI deep learning algorithms to ultimately confirm whether the target detection object is qualified.

|

Project |

Performance index |

|

Machine application |

Used to detect the indentation of ACF conductive particles and bonding foreign objects on the COG and FOG parts of the LCD panel bonding section, and to judge the OK/NG of the panel according to certain standards |

|

Testing items |

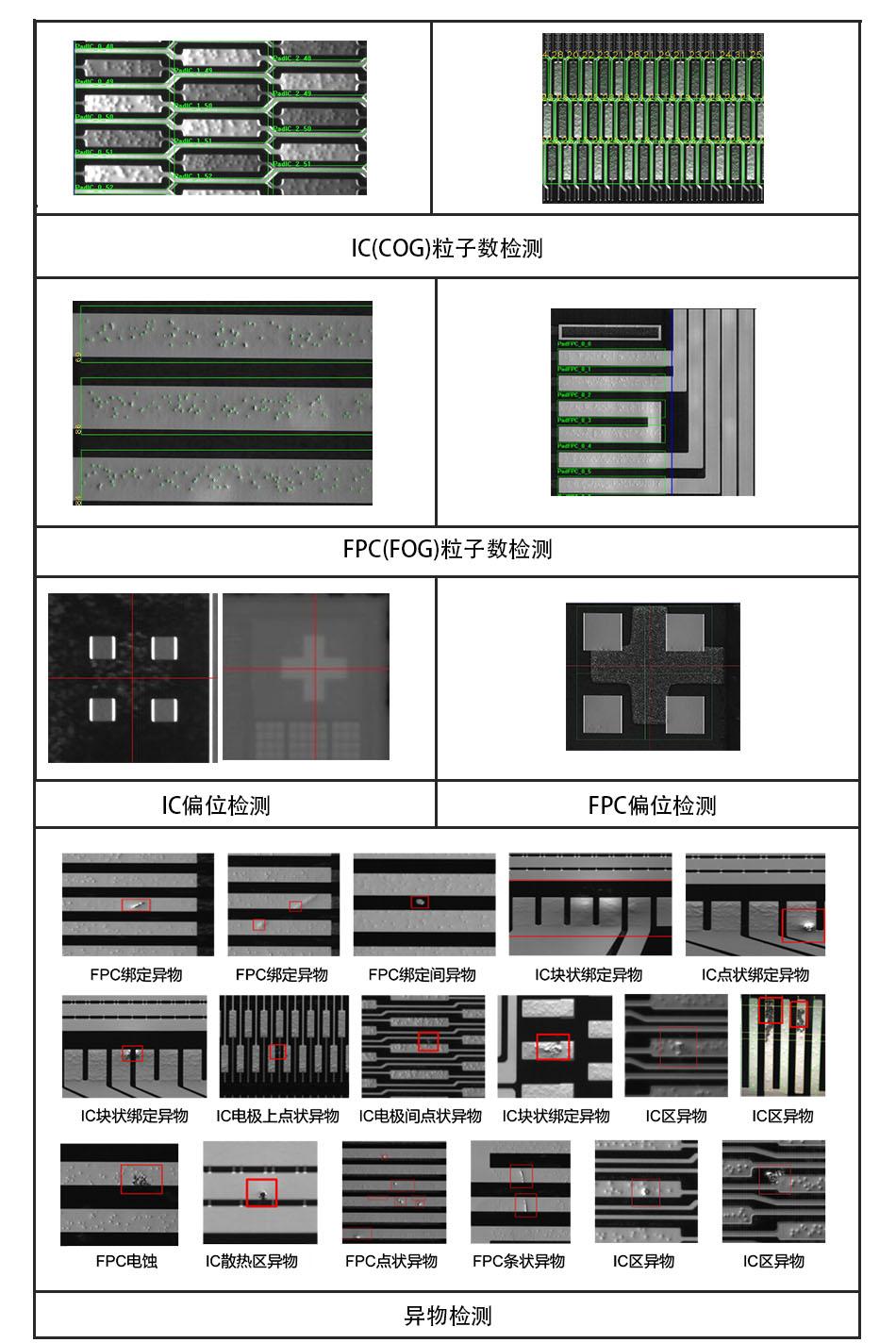

Detect the quantity (leakage pressure, particle shortage), distribution, and indentation strength (overvoltage, shallow pressure) of conductive particles on IC and FPC |

|

Detecting IC and FPC misalignment |

|

|

Detect foreign objects, corrosion, scratches, cracks, fragments, dirt, Dimple and other defects in the scanning area |

|

|

Imaging system |

DIC differential interference phase contrast microscope component, customized objective lens, customized light source, real-time laser automatic focusing |

|

Using a line scan camera to image the Bump area on the COG and FOG of the LCD panel |

|

|

Optical accuracy |

0.5um / Pixel |

|

Detection time |

7 Inch Panel Double Steps ≤ 17sec |

|

False alarm rate |

≤1% |

|

Particle detection |

Deviation in detecting the number of conductive particles on the same IC Bump/FPC electrode: When the total number of conductive particles is ≤ 10, the detection deviation is ± 1 particle/Pump When the total number of conductive particles is greater than 10, the detection deviation is ± 10%/Pump |

|

Deviation detection |

Detect the X and Y direction deviation of the IC (using an IR camera): Detection accuracy ± 1.5 μ m; Continuous testing for 30 times, with a repeat deviation of ≤ 3 μ m |

|

Detect the X and Y direction deviation of FPC: Detection accuracy ≤± 3 μ m; Continuous testing for 30 times, with a repeat deviation of ≤ 6 μ m |

|

|

Particle distribution offset detection: detection accuracy ± 3 μ m |

|

|

Others |

Fully automatic visual alignment: After initial calibration of the feeding CCD, the platform undergoes secondary high-precision calibration Motion system: high-precision linear motor, driven by DD motor |

Defect image