The ITO line AOI inspection machine (also known as the step electrode automatic inspection machine, terminal scratch automatic inspection machine) is mainly used for defect detection of ITO in the exposed area of TFT-LCD lines, improving production line yield and the process control capability of manufacturers. Mainly detecting scratches, short circuits, open circuits, micro breaks, foreign objects (dirt), corrosion, burrs, etc. The equipment can be widely used in fields such as TFT-LCD industry, touch screen industry, photovoltaic industry, and LED industry, achieving rapid detection of ITO lines, silver paste lines, etc. on glass substrates or flexible substrates (PET, CPI, etc.).

|

Item |

Parameter |

|

|

|

Model |

D3 offline series/D4 online series |

|

Machine Vision System |

LCD Size |

TFT-LCD size: 1.8-40 inches, maximum 1000 x 480mm, suitable for detecting irregular screens |

|

Check Area |

Covering the entire glass ITO circuit, including Fanout area circuit, CFOG Pad area circuit, etc. (beyond 15um from the edge of the TFT polarizer) |

|

|

Line Type |

Detect straight lines, wavy lines, corner lines, cross lines, bright and dark lines (contrast differences), bonded area blocks, etc., and filter out misjudgments caused by IC pad lines, ACF cured colors, line intersections, etc |

|

|

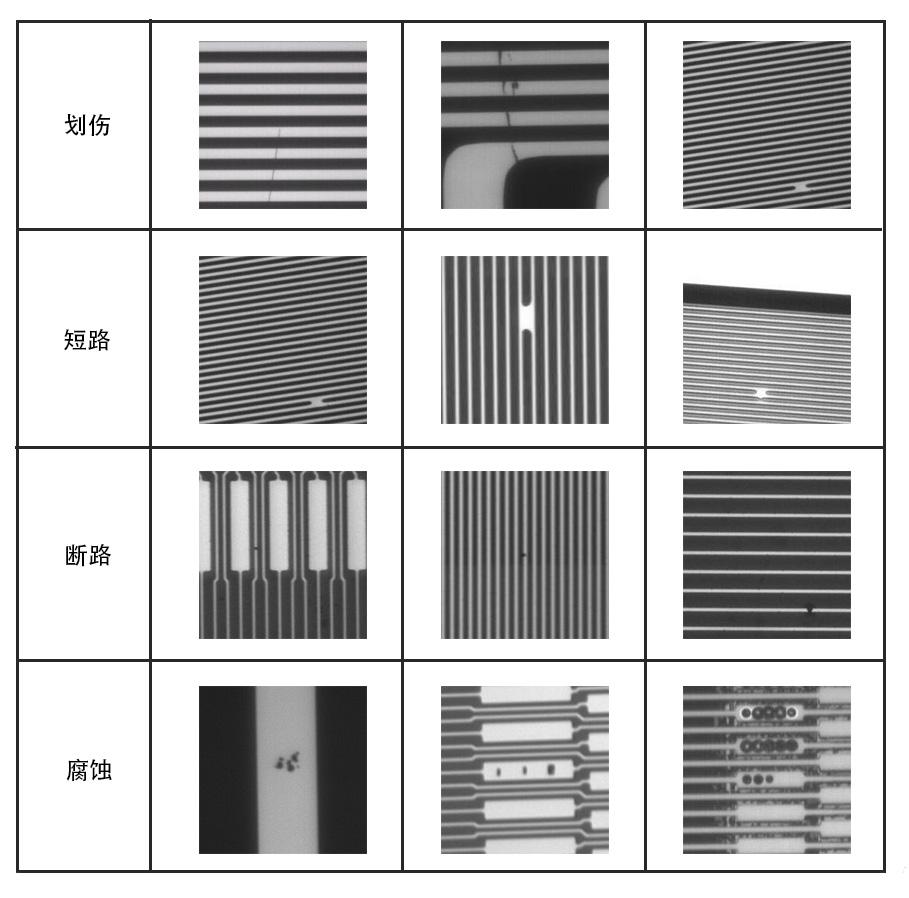

Defect type |

Line scratches, micro scratches, short circuits, open circuits, micro breaks, foreign objects (dirt), corrosion, burrs, etc |

|

|

Accuracy |

Minimum detectable defect size 2um × 2um |

|

|

Leakage |

0 DPPM (missed detection rate: number of missed detections on the production line/number of scratches during inspection) |

|

|

Over Kill |

<5%, with an average misjudgment of<2 images/piece |

|

|

Operating Rate |

>90% |

|

|

*Takt Time |

7-12 Inch Panel Double Steps ≤ 7sec |

|

|

12-17 Inch Panel Double Steps ≤ 10sec |

||

|

17-24 Inch Panel Double Steps ≤ 12sec |

||

|

24-45 Inch Panel Double Steps ≤ 15sec |

||

|

Model Change |

New model switching time:<60 minutes |

|

|

Existing model switching time:<20 minutes |

||

|

optical system |

Area array high-precision camera |

|

|

Customized coaxial light source |

||

|

Customize high-resolution 4X or 10X objective lenses based on actual needs |

||

|

Visual Positioning |

Support panoramic positioning or Mark positioning |

|

|

Electromechanical system |

Sheet metal frame structure+marble platform to enhance equipment stability and plane reference |

|

|

Using a dual head linear motor for transplanting and transporting materials, with high precision and speed |

||

|

The testing institution adopts high-precision linear motor with a resolution of 0.1um |

||

|

Adopting DD motor rotating platform, high-precision and high rigidity |

||

|

Adopting servo motor and high-precision screw module, used for material code reading, visual positioning calibration and other mechanisms |

||

|

Adopting SMC pneumatic and vacuum system |

||

|

Loading and unloading |

Card clip storage mode |

|

|

Tray disk storage mode |

||

|

CV transmission mode |

||

|

Material box conveying mode |

||

|

Cell Transfer |

CV conveyor, anti-static belt conveyor |

|

|

Four axis/six axis robot handling |

||

|

Multi axis servo motor+linear module architecture for transportation |

||

|

Forklift handling and transportation |

||

|

Flip over |

||

|

Software System |

Otek with proprietary intellectual property rights ® AOI Industrial Application Testing Software |

|

|

Usability: intuitive and user-friendly graphical display interface, intelligent parameter setting function |

||

|

Humanized, optional alarm function, and customizable alarm function (such as defect rate upper limit alarm function) |

||

|

Quick switching function: Different products can edit and call different recipes |

||

|

Data security and fast positioning: Abnormal images can be 100% saved and retained: OK saved image+NG thrown material saved image; The image can be zoomed in and out, and the abnormal location of AOI inspection can be identified; Abnormal images stored for more than three months, with a minimum storage space of 2T |

||

|

Advanced permission settings: equipped with a window for adjusting the interception rate and setting different permissions |

||

|

Quick integration with customer information system interface: The detection result data can be saved and uploaded to the CIM system |

||

|

Algorithm |

Algorithm |

Otek ® AOI detection algorithm+AI artificial intelligence re evaluation system |

|

QR codes |

Supports reading multiple Vericode codes, corresponding to Normal Type, Normal HD Type Vericode, Outline Type Vericode, and DM Type Vericode |

|

|

Other |

Safety |

Safety grating/safety door lock: used for personnel safety protection |

|

FFU: Used for clean equipment to achieve Class 1000 and Class 100 cleanrooms in internal spaces |

||

|

Static electricity: The material in contact with the product is made of anti-static material and equipped with an ion air rod to eliminate static electricity |

||

|

Power |

AC 220V±10% 50~60Hz |

|

|

Grounding |

The resistance between any two grounding points of the entire machine is less than 5 Ω |

|

|

Ionizing Air Blower |

The ion dissipation rate in the homework area is less than 5 seconds; Ionic equilibrium voltage within 100V |

|

|

Environment |

Temperature: 5-40 ℃ |

|

|

Humidity: 25~85% RH (without condensation) |

||

|

Temperature |

<40℃ |

|

|

Positive pressure |

0.5~0.6MPa, access port provided by the manufacturer |

|

|

Negative pressure |

-80kpa, access port provided by the manufacturer |

|

Defect image