The glass cover of a mobile phone is the outermost glass of the touch screen. With the rise of smartphones, glass covers are widely used in the electronics industry. They are attached to the surface of touch screens to protect the screen and beautify products. The automatic detection of cover defects in the field of smartphones is considered a technological bottleneck that has plagued the industry for many years. The detection of surface defects in products requires high detection accuracy and reliable lighting effects to ensure, especially for the detection of glass cover plates after lamination, which is more difficult. At present, the device can detect white film and silk screened cover plates, and is compatible with the detection of 3D glass cover plates. It can also detect defects in car glass screens and TFT-LCDs.

|

Project |

Performance index |

|

|

Detection system |

Product size |

MAX: 17.3 inches (230 × 390mm) |

|

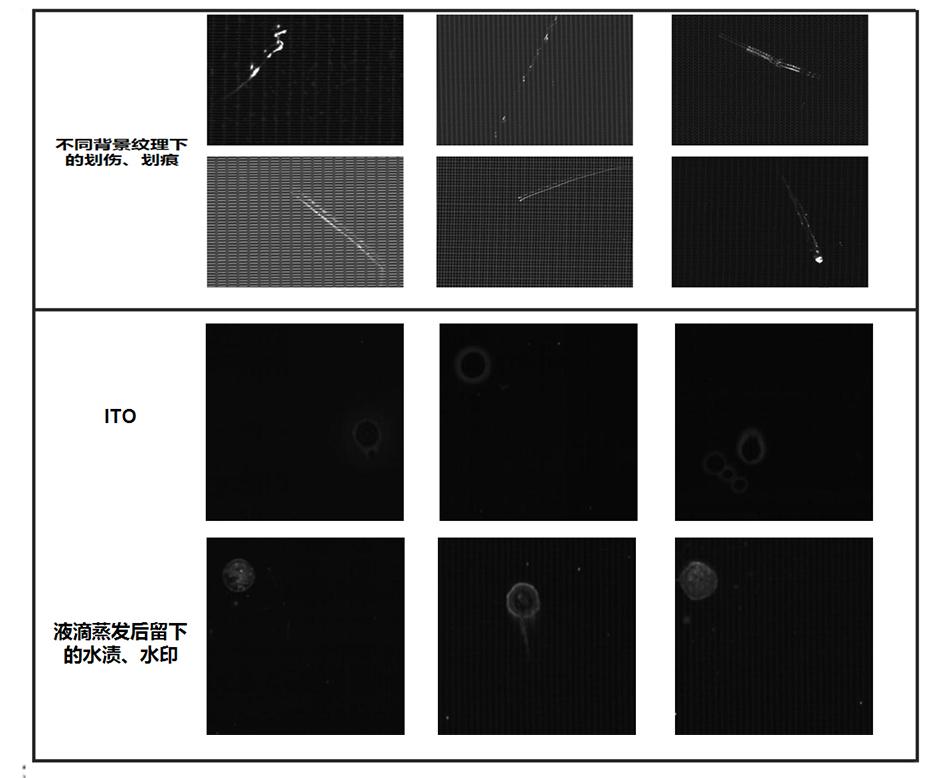

Testing items |

Foreign objects, stains, scratches, dents, bubbles, water stains, cracks, broken edges, broken corners, discoloration, poor screen printing, and fragments, etc |

|

|

Detection speed |

According to the actual speed of the production line (two line speeds: one 25 seconds and one 10 seconds) |

|

|

Detection accuracy |

Detected specification:>100um |

|

|

Loss inspection rate |

<0.5% |

|

|

False alarm rate |

<3% |

|

|

Structural Requirements |

Offline machines, or installed above existing production lines, with other control systems, PCs, and AI systems externally mounted |

|

Defect image