TFT-LCD online foreign object line inspection machine is an AOI equipment used to detect product defects before and after bonding of LCD panels. It mainly detects foreign objects, corrosion, scratches and other defects, thereby improving production line yield and the manufacturer's process control capabilities.

|

Item |

Parameter |

|

|

Check Area |

Before or after the COG/FOG process of the TFT-LCD, defects such as foreign objects, corrosion, and scratches are mainly detected to prevent defective products from flowing into the next process. |

|

|

Model |

DF series |

|

|

Machine Vision System |

LCD Size |

TFT-LCD size: 7-32 inches, Max:800 x 450mm, Suitable for detecting irregular screens |

|

Check Area |

ITO line area, IC lamination area, FPC lamination area |

|

|

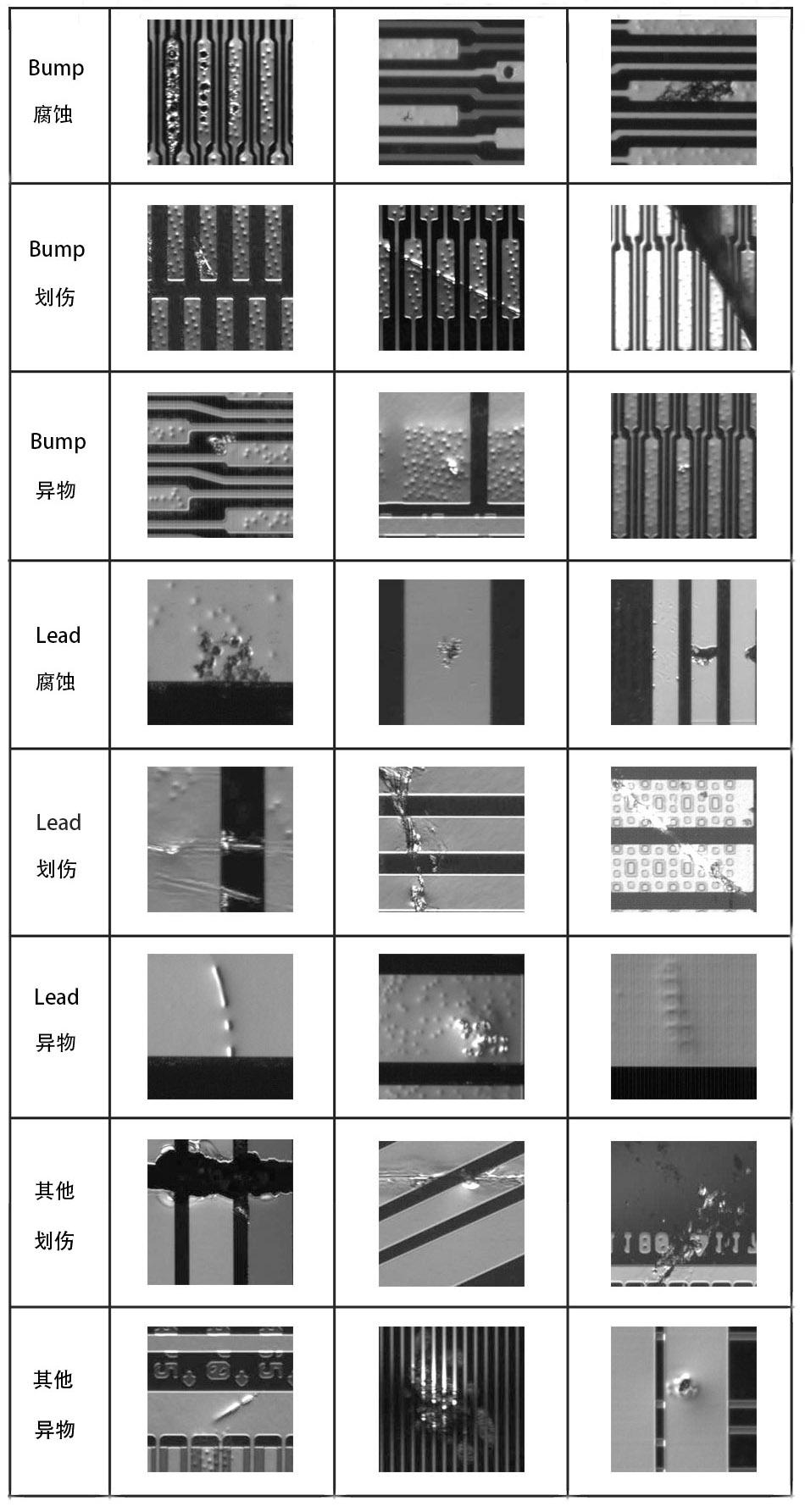

Defect type |

ITO line area inspection: scratches, fragments, corrosion, materials, etc IC/FPC compression zone inspection: foreign objects, scratches, fragments, corrosion, materials, etc |

|

|

Accuracy |

Foreign object detection: minimum detection size 30um x 30um |

|

|

Line corrosion inspection: solvent residue, sweat stains, dirt; Minimum detection size 30um x 30um |

||

|

Line corrosion inspection: solvent residue, sweat stains, dirt; Minimum detection size 30um x 30um |

||

|

Line scratch inspection: minimum inspection size 20um x 20um |

||

|

OverKill |

<1% |

|

|

Takt Time |

12.3” Tact Time:T/T≤12sec 20.3” Tact Time:T/T≤20sec 30.45” Tact Time:T/T≤28sec |

|

|

Operating Rate |

≥90% |

|

|

Model change |

Model changeover time:<0.5 hours Model campus time:<1 hour |

|

|

Electromechanical system |

Material handling, using a double headed linear motor for transplanting, with high precision and speed; |

|

|

Adopting linear motor line scanning imaging acquisition, with a motion resolution of 0.1um; |

||

|

Adopting DD motor rotating platform, high-precision and high rigidity; |

||

|

Using servo motors and high-precision modules for material handling, visual positioning calibration and other mechanisms; |

||

|

Adopting SMC pneumatic and vacuum system for product handling, adsorption, etc. |

||

|

Software System |

Otek AOI automatic optical inspection software and AI re evaluation system; |

|

|

Abnormal operations require the machine to have an alarm function, and the number of records saved for machine alarms should be greater than 100; |

||

|

Different products can be edited and different recipes can be called; |

||

|

Abnormal images can be saved with 100% image retention: OK save image+NG throw material save image; The image can be zoomed in and out, and the abnormal location of AOI inspection can be identified; |

||

|

Having a window for adjusting the interception rate and setting different permissions; |

||

|

Upper limit alarm function for defect rate; |

||

|

Industrial control host/workstation, with abnormal image storage time greater than three months and storage space of at least 2T; |

||

|

Save the detection result data and upload it to the CIM system. |

||

|

optical system |

TDI camera, resolution 5um, FOV 4.5mm |

|

|

Microscopic lens+four high brightness light sources |

||

|

Computer System |

Computer System |

Detect two hosts, I5CPU, 8GB or more memory, 21 "LCD, touch screen |

|

AI Server |

Configuring a high-performance AI artificial intelligence server with multiple GPUs |

|

Defect image